- 24 Kembla Street Cheltenham Victoria 3192

- 03 9584 7077

- sales@hmpg.com.au

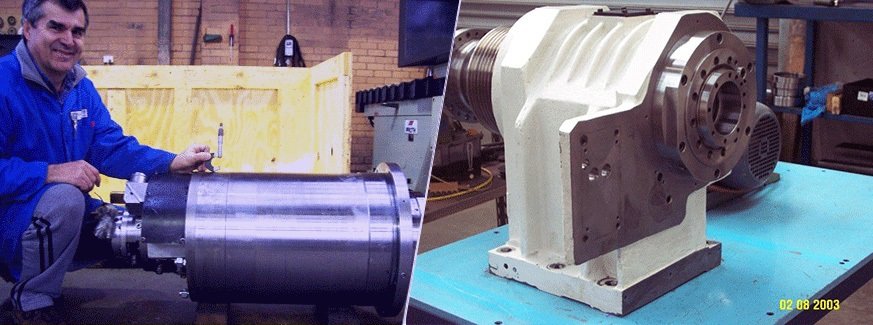

We know that your CNC spindles were designed specifically to achieve the best performance in your machines.

Due to this, we use repair techniques that ensure that spindle performance is not compromised.

We offer repair on CNC lathe and CNC machining centre spindles.

Our quality assurance procedures ensure that you have a reliable, accurate, and long-lasting spindle.

Most are supplied with a test certificate.

Click here to read the Terms and Conditions of our Spindle Warranty